Precision Mold Manufacturing Enhances Quality of Automotive Injection Molding Parts

Feb 12,2026Growing Demand for Electrical Injection Molding Accessories in Smart and Electric Systems

Feb 05,2026Automotive Injection Molding Parts Drive Lightweight and High-Precision Vehicle Manufacturing

Jan 29,2026The Growing Importance of Electrical Plastic Injection Molding Accessories

Jan 22,2026The Role of Precision Injection Molding in Automotive Manufacturing

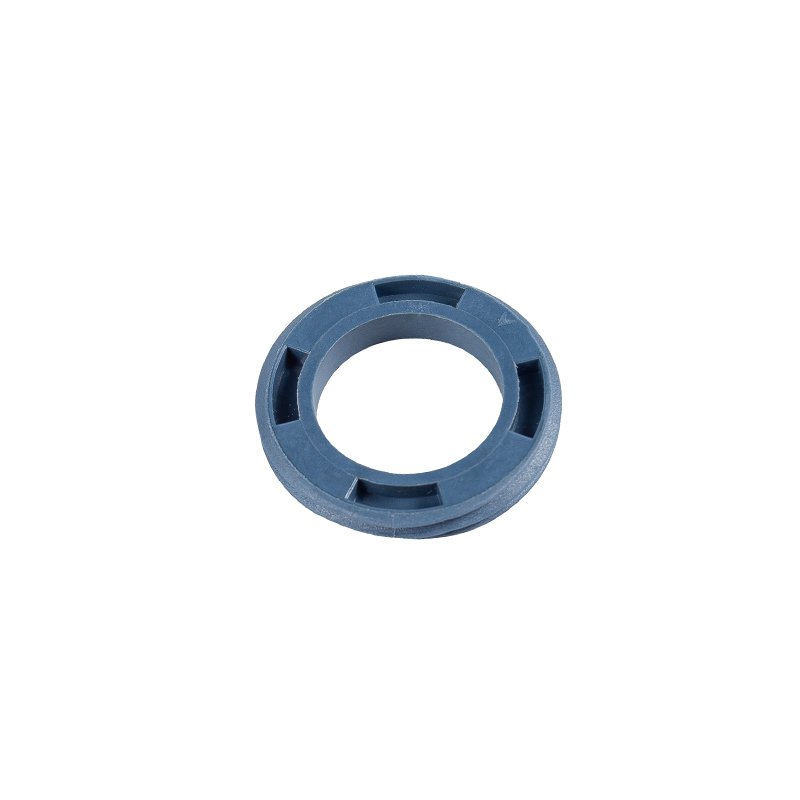

Jan 15,2026In the wave of modern technology, water quality detectors, as crucial tools for safeguarding our drinking water safety and environmental health, have their performance directly tied to the accuracy of results and reliability of use. However, while many may focus on their core sensors and main control chips, they often overlook the humble injection-molded components that form their sturdy casings and precise internal structures. It is these seemingly trivial plastic parts, meticulously joined like building blocks, that collectively forge the detector’s excellent quality. They must not only fit perfectly but also possess exceptional physical and chemical properties to resist erosion from various complex environments. From a 1.5-gram fixing ring to complex internal brackets, every precision injection-molded part bears the responsibility of ensuring stable equipment operation. They are the skeleton of the water quality detector and a robust barrier protecting its sensitive components from external interference—their importance is no less than that of any core electronic component. It can be said that without these high-quality injection-molded parts, even the most advanced sensors cannot exert their intended effectiveness.

Water quality detectors often operate in complex and variable environments, potentially involving extreme conditions such as moisture, acids, alkalis, or high temperatures. This requires every component of the device to exhibit excellent durability and stability. Against this harsh backdrop, the importance of precision injection-molded parts becomes evident.

For example, a 1.5-gram fixing ring used to secure a sensor directly impacts the sensor’s installation position and measurement accuracy. Even a slight dimensional deviation could prevent the sensor from being firmly fixed, causing displacement during transportation or use and thus affecting reading precision. Additionally, these parts must have good corrosion resistance to ensure they do not deform or degrade when in long-term contact with water or chemical reagents, which would shorten the device’s service life. They serve as bridges connecting, supporting, and protecting all internal precision components of the detector, and their quality directly determines the overall reliability and durability of the equipment.

The creation of precision injection-molded parts is a complex process integrating design, materials, and craftsmanship. Its core lies in the sophistication of mold design. For micro-components like the 1.5-gram fixing ring in water quality detectors, the mold’s precision requirements are extremely high, with tolerances as small as a few microns. Mold designers must accurately calculate the shrinkage rate of plastic during cooling to ensure the final product meets dimensional specifications.

Meanwhile, the design of the mold’s runner system is critical, as it determines whether molten plastic can fill every corner uniformly and quickly, avoiding bubbles or incomplete filling. During manufacturing, advanced injection molding machines provide precise control over injection speed, pressure, and temperature, ensuring that every precision injection-molded part for water quality detectors can perfectly replicate the mold’s microscopic details. This relentless pursuit of detail is the key to forging these microscopic wonders and the source of high-quality water quality detectors.

The casing of a water quality detector is the first interface users interact with, and its design not only affects the device’s appearance but also directly impacts user experience and service life. An excellent casing design must first prioritize practicality. It needs to use durable materials such as PC or ABS alloys to resist accidental drops and impacts.

Simultaneously, the casing’s structural design must account for waterproofing and dustproofing needs, with well-designed sealing grooves and卡扣 (clips) to protect internal sensitive electronics from liquids or dust. Secondly, ergonomic considerations are essential—a casing with a comfortable grip and logical button layout significantly enhances user convenience.

In terms of aesthetics, the casing’s color, surface treatment, and shape determine the device’s overall texture and brand image. Through refined injection molding processes, various colors and surface textures can be achieved, allowing the detector to meet functional needs while offering a visually pleasing experience.

In a fiercely competitive market, many water quality detection equipment manufacturers face challenges of product differentiation and rapid market entry. Here, customized services for high-precision injection-molded parts become a key solution. Customization not only meets customer needs for non-standard parts, special materials, and complex structures but also strongly supports new product development.

For instance, when a research team designs a new water quality detection technology requiring a custom complex-structured precision injection-molded part, professional high-precision injection molding service providers can respond quickly. They offer end-to-end technical support, from designing the 1.5-gram fixing ring mold to prototyping, testing, and final mass production. This close collaborative model drastically shortens new product launch cycles, helping customers seize market opportunities. The customization path, in essence, combines innovation and efficiency, turning unique design concepts into reality and unlocking infinite possibilities for water quality detection equipment innovation.

The quality of injection-molded parts does not merely affect individual components—it directly impacts the overall quality of water quality detection devices. An inferior injection-molded part may not show issues immediately, but over time, material aging or dimensional deformation could cause internal components to loosen, poor contact, or even functional failure.

In contrast, high-quality injection-molded parts for water quality detectors ensure long-term stable operation in harsh environments, effectively reducing failure rates and after-sales maintenance costs. For end-users, this means more reliable measurement results and peace of mind. For manufacturers, consistently delivering high-quality equipment builds brand trust and earns long-term market recognition. Thus, prioritizing quality control of injection-molded parts during production is key to enhancing equipment quality and gaining a competitive edge in the market.

Copyright © Suzhou Huanxin Precision Molding Co., Ltd. All Rights Reserved. Custom Plastic Injection Molding Supplier